Circularity, or a circular economy, is a system focused on sustainability and the elimination of waste by keeping products in circulation for as long as possible.

While circularity applies across industries, it’s especially important in the electronics or IT industry. From OEM to refurbishing, the circular approach to IT has the vast potential to conserve resources, extend the lives of products, and prevent waste.

Before we discuss how to drive circularity through the electronics lifecycle, we need to first understand why it’s necessary.

Current Challenges: How We’re Falling Short

Circularity stands in stark contrast to the linear economy: the linear economy is the traditional model where raw materials are taken and transformed into products for consumer-use until they’re discarded, with no concern for their ecological footprint.

The effects of the linear economy in the IT industry are especially concerning. According to The Association for the Advancement of Sustainability in Higher Education (AASHE), “Toxic e-waste is the fastest growing waste stream in the world, at an annual rate of over 50 million metric tonnes.”

The harmful effects of e-waste are bad enough as it is. But even more concerning are the greenhouse gas emissions from electronics manufacturing, use, distribution, and disposal. These emissions contribute to global warming and climate change.

Companies like Samsung and Dell have begun to acknowledge their responsibility as manufacturers to take action in driving circularity. This is a step in the right direction, but it’s time for the rest of the technology industry to follow their lead.

How To Drive Circularity Through the Electronics Lifecycle

Repowered is proud to be a NAID-AAA and R2 certified IT Asset Disposition (ITAD) Vendor. That means when it’s time to get rid of your electronics, you can trust us to recycle and dispose of these devices ethically and sustainably.

But, while recycling your e-waste is a vitally important part of the sustainable technology lifecycle, circularity entails much more than that. True sustainability means focusing on the entire electronics lifecycle.

Circularity at OEM

Circularity must begin at manufacturing. As we mentioned before, most emissions happen during the manufacturing and pre-manufacturing processes. The emissions from these initial processes are significantly higher than any they are in other stage of the electronics lifecycle.

For example, the pre-manufacturing processes of the Samsung Galaxy S6 accounted for more than half of all the emissions in its entire lifecycle.

So what are some actionable steps companies can take to minimize their carbon footprint during manufacturing? According to the Electronic Products & Technology, manufacturers should be designing products with a focus on reuse, recovery and/or recycling. They should be considering both durability and restorability in a model that intends to:

- Minimize the use of raw materials

- Maximize the useful life of materials and other resources through resource recovery

- Minimize the waste generated at the end-of-life of a product and its packaging

Essentially, along with reducing the amount of raw materials needed to produce electronics, manufacturers need to be intentional about their product’s entire lifecycle—not just its efficient production. Sustainability starts with them.

Circularity in Repair

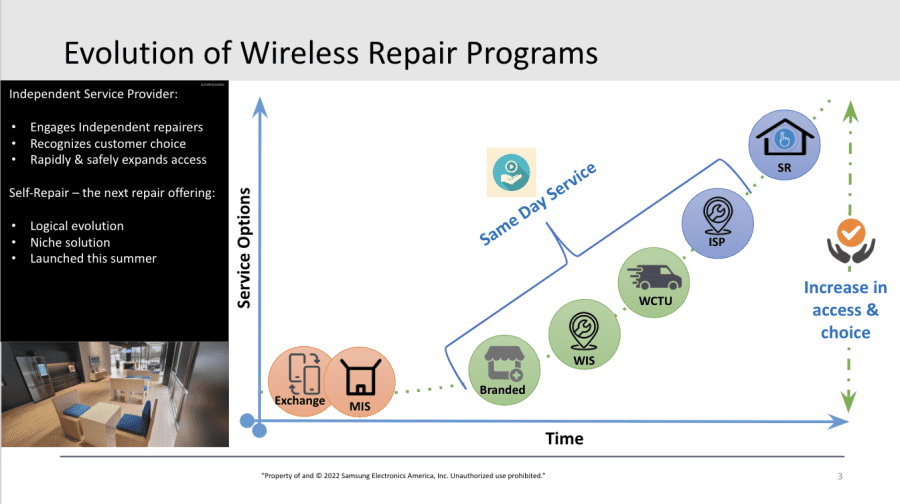

A circular economy is needed in electronics repair programs as well. Samsung, for example, has evolved their wireless repair program to embrace more sustainable practices.

The evolution of this program plots a course that other companies can follow:

- Samsung’s repair process began with the carrier-driven seed stock based exchange model. This model was wasteful, expensive, and received poor feedback regarding customer experience.

- Then Samsung began offering the customer mail-in option, through which electronics could be shipped to a centralized repair depot. While this improved customer experience, it was less easy to use than the previous model.

- Same-day service came in as a much more convenient model that quickly became customers’ go-to choice for wireless repair. This option was more eco-sensitive and came with a host of other benefits.

- The company then expanded their wireless repair program to include Independent Service Providers, which recognized customer choice and expanded access.

- Finally, Samsung launched the self-repair program this past summer. With this program, customers can easily perform repairs themselves, encouraging longer use and reuse of electronic devices—both of which are key to creating a circular economy.

Drive circularity through your IT assets by developing an effective, secure and profitable IT asset disposition (ITAD) program for your business! Our FREE GUIDE will show you how!

Circularity in Reuse

There are many ways in which a circular economy can be created through reuse of electronics.

For example, electronics can be recycled through a manufacturer take-back program, or through accredited recyclers like Repowered.

The electronics recycling industry is largely unregulated, so make sure your recycler is accredited. Repowered is a NAID-AAA and R2 certified IT Asset Disposition (ITAD) Vendor, which means your electronic waste will be recycled and disposed of ethically and sustainably.

Additionally, instead of buying new electronics, consumers should consider upgrading their electronics, selling their old electronics to a refurbisher, and buying refurbished.

(Check out one of our recent blogs for some cool refurbished tech gift ideas for the Holidays.)

Consumers can also extend the life of old devices by using cloud-based operating systems that won’t put strain on the hardware.

Circularity in Design

Designing electronics for circularity means:

- Making it easy to harvest parts and recover materials to reuse, recreate, and recycle.

- Creating modular designs for simplified access to components and easy repairs.

- Reducing materials needed, optimizing and streamlining architecture

- Engineering for durability, extending life where possible

- Building with circular or reduced-impact material choices, using high grade material streams

- Providing product take-back, cascaded ownership, and as-a-service offerings.

A great example of a company that’s embraced circularity in their design is Dell. Dell has committed itself to increasing circularity in design through Concept Luna, a proof-of-concept that explores revolutionary design ideas to make components immediately accessible, replaceable, and reusable. This reduces resource use and keeps even more circular materials in the economy. Check out their video below:

Dell designs their laptops for durability, easy repair, easy recycling, and with less materials. All of this combined means that Dell laptops are designed for 50% carbon reduction! That’s a major step toward the future of sustainable technology.

The Goal of Circularity in the Electronics Lifecycle

On the side of both manufacturers or consumers, the bottom line is: The longer a product is in use, the less impact it will have on the environment.

Longer use of sustainable technology is the ultimate goal of recycling, reuse, and refurbishment. Longer use can be encouraged by service agreements, easy maintenance, product sharing, and cloud-based operating systems.

Even small changes toward extending the electronics life cycle can reduce the carbon footprint by significant amounts.

According to AASHE, “Even a one-year product life extension has a substantial impact. Keeping notebook computers in use for five years instead of four reduces greenhouse gas emissions by 64.9 kg carbon dioxide equivalent per notebook, or 17.4 percent.”

To help care for our planet and impact the lives of many, we all need to do our part when it comes to driving circularity through the electronics lifecycle. If you’re a company that would like to start an ITAD partnership with Repowered, or if you’re a consumer who has questions about your e-waste recycling needs, give us a call at 612-294-0578!

Recent News & Articles

Spotify Car Thing: What To Do Once The Device Stops Working

Second Chance Month: Why Fair Chances Are So Important